Modernization & heat pump integration in the Saalfelden heating plant

THERMAFLEX DEMO PROJECT: Increased efficiency of the existing biomass boiler

This demo is part of the lead-project ThermaFLEX that has been completed. Download the ThermaFLEX Publishable Final Report here.

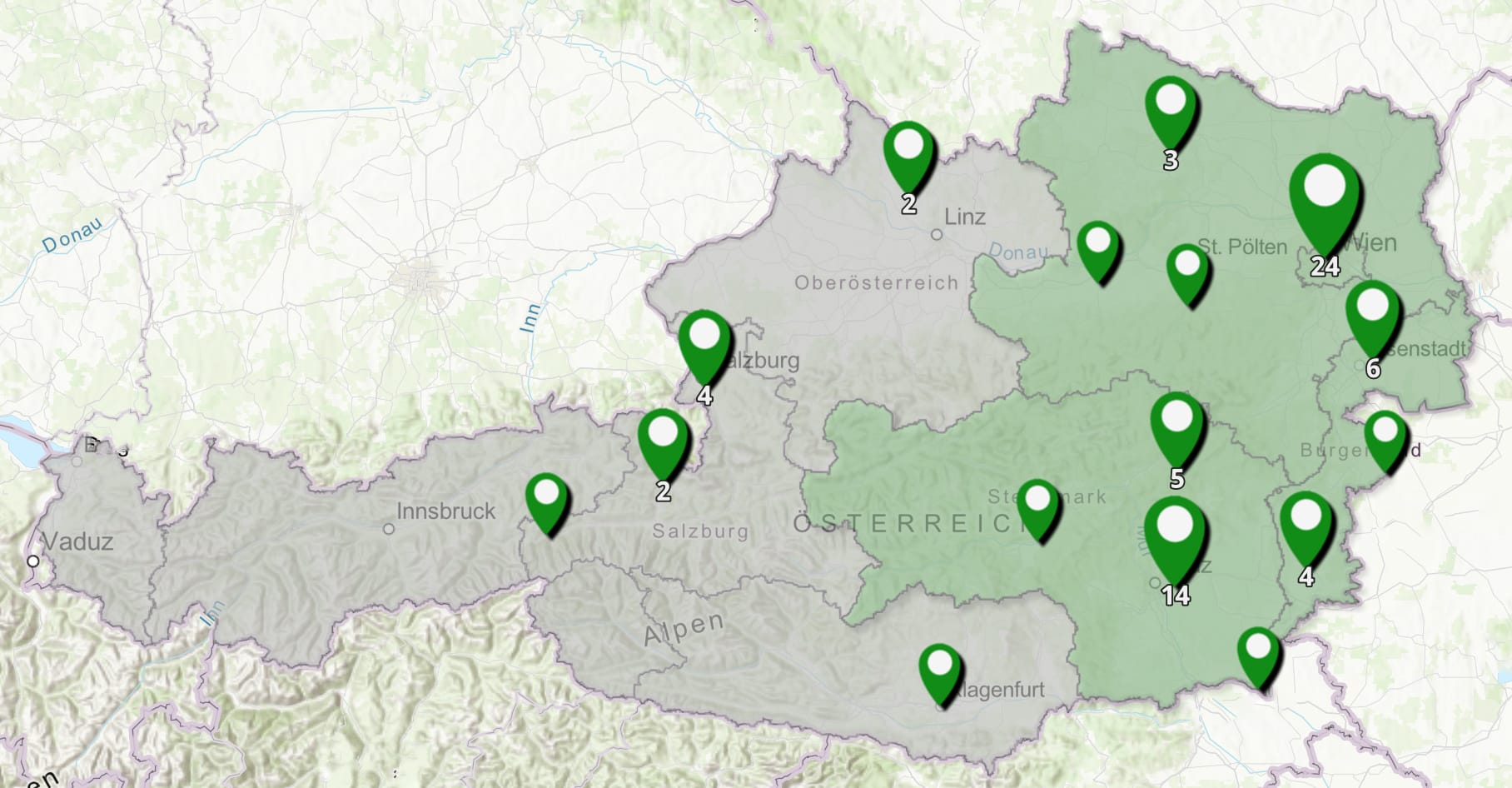

To comprehensively demonstrate and evaluate a modernisation concept combined with the integration of a heat pump, a two-stage modernisation process was started in the Saalfelden heating network (built in 1997, network length: 5.3 km, around 50 customers, heat generation in 2017: 13 GWh).

In the first stage (completed in autumn 2020), the existing heating network underwent a comprehensive modernisation. This involved carrying out a wide range of measures at the existing heating centre (adaptations to the existing biomass furnace including increasing the performance of the flue gas condensation and improved flue gas cleaning, implementation/ renewal of the control technology, implementation of buffer storage and buffer management, implementation of a flue gas cleaning system in combination with flue gas condensation etc.) and in the heating network (targeted network expansion, optimisation of network temperatures, renewal of the thermal hydraulics etc.).

After completion of stage 1, the modernisation measures were subjected to comprehensive monitoring and evaluated. The modernisation led to a significant increase in the energy efficiency of the existing biomass boiler and a reduction in the proportion of fossil fuels in the energy mix. For example, the proportion of fossil energy (gas boiler) in the winter months of 2021 was reduced from around 25% to less than 5% in January and from 15% to around 0.5% in February.

Based on the results and findings of stage 1, technical concepts for integrating a heat pump to further increase efficiency and further increase the proportion of renewable energy in the energy mix were developed for stage 2 and should subsequently be realised (in the course of 2022). In the next step, the integration of the heat pump led to a further increase in performance and efficiency, but also to the optimisation of heat recovery from the flue gas. The flue gas condensation served as the heat source. By further cooling the return flow of the flue gas condensation from currently approx. 52°C to approx. 35°C, a considerable increase in the efficiency of the flue gas condensation was achieved. The district heating return serves as a heat sink. The energy is therefore used in the boiler circuit to preheat the boiler water.