DOPPLER

Digital optimisation platform for district heating systems

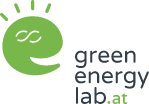

Biomass district heating systems are an important contribution to the realization of a sustainable energy supply and promote regional value creation. The efficient and low-emission operation of such plants requires intelligent interaction between energy supply, storage and distribution. This allows to adjust the load distribution to the optimal operating conditions of the heating system, taking into account the user requirements.

Most district heating systems are controlled based on current power demand. This means that the output of the heat generator is always adapted to the current demand of all heat consumers, which, however, sometimes leads to unfavorable operating points with low efficiencies and high emission values. The demand-oriented mode of operation additionally complicates plant dimensioning and leads to high, short-term peak loads and thus to an oversizing of the heat supply plants. This has a negative impact on efficiency and investment costs. Fossil-fired peak load boilers or generously dimensioned short-term storage (e.g. daily storage) are used for compensation.

Objective of the DOPPLER project

The aim of the project was to implement decentralised optimisation measures based on demand response. A system-wide platform for district heating planning, operation and optimisation that integrates all components such as generation, distribution and consumption has been developed. A strong focus was on the integration of end customers.

The measures implemented in DOPPLER were intended to increase the overall efficiency of district heating systems and reduce CO₂ emissions. The system-wide platform is suitable for upscaling to larger networks. The project demonstrated how municipal heating networks can be made more efficient through the use of digitalisation, real-time data and user integration.

Approach and methodology of the DOPPLER project

Technology provider Arteria Technologies brought its existing district heating simulation platform to DOPPLER. Another innovative point was the connection of the Arteria platform with MEO Energy’s smart home system (MEO Controller), which allows secondary-side flexibilisation potentials (PV, heat pump, thermal storage) to be used for demand response programs.

End users are integrated through a motivation system based on gamification methods developed by the Industrial Science Institute, which focuses on socio-economic aspects of demand response such as load shifting through behavioral changes, remote control of buffer storage or reduction of secondary side supply temperatures.

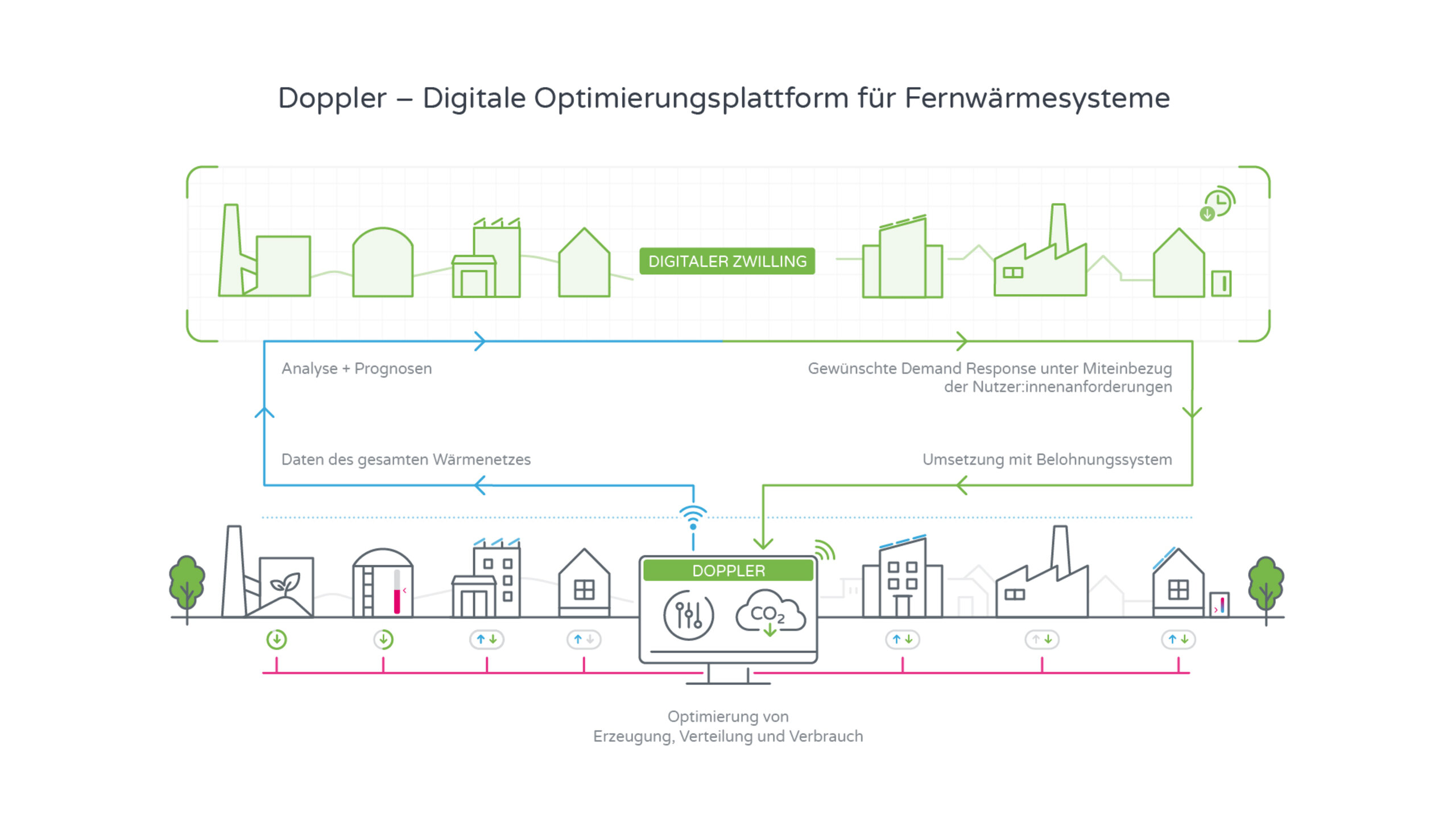

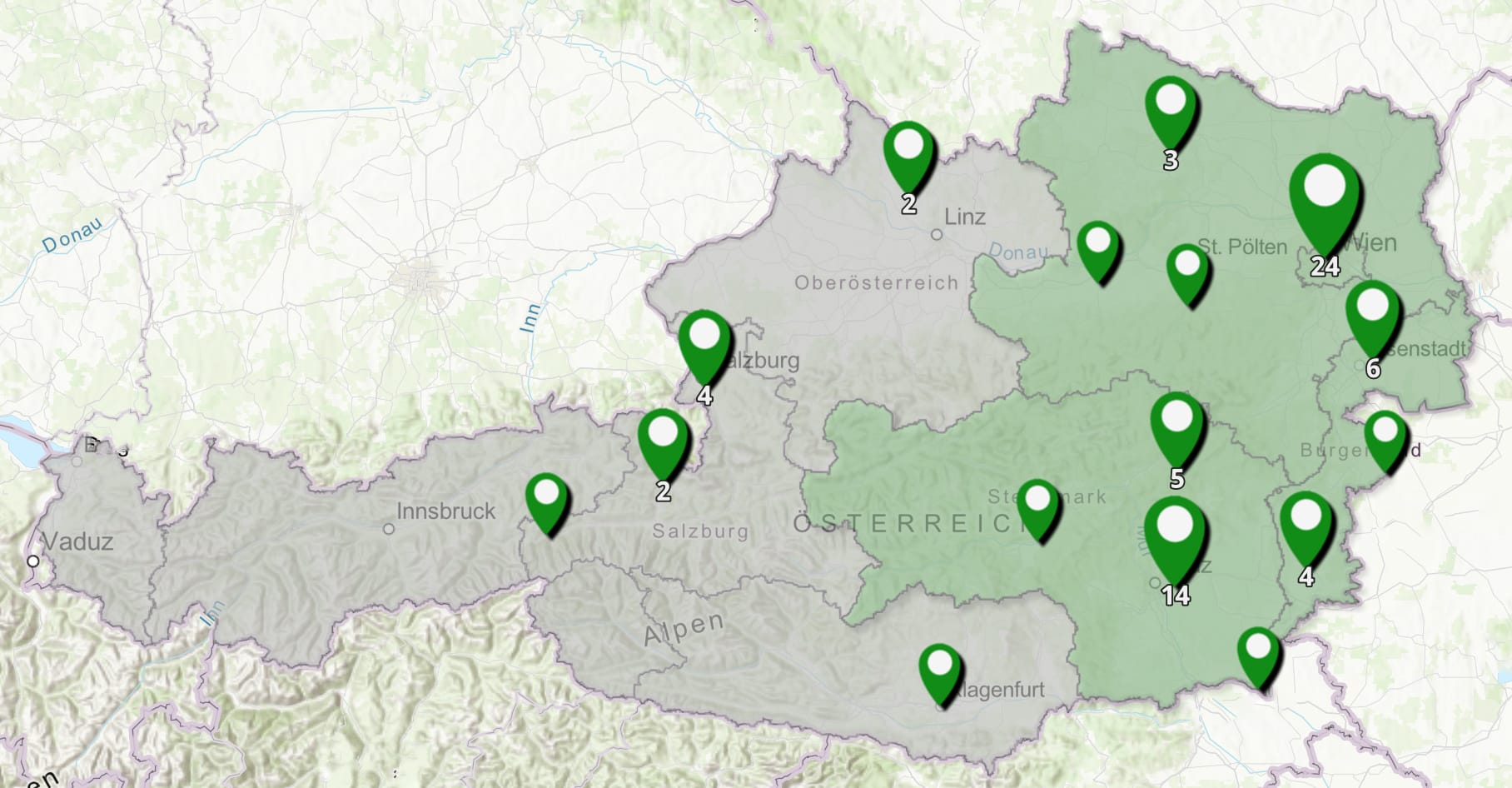

The system-wide platform will be demonstrated at four representative locations in Austria (district heating networks of Güssing, Mischendorf, Japons and Rohrbach). A “digital twin” (a digital representation of the heating network) will be created for each of these four demonstration sites. Depending on the equipment of the demonstration networks, this will also be linked to the real-time data acquisition of the district heating networks.

The digital twin can be used as a tool for identifying errors and for raising awareness. In Rohrbach, the MEO controller continuously generates relevant insights into the usage behaviour, system responses and flexibility.

Despite challenging conditions in some areas, the development of interfaces for integration of data represents an important milestone in the project:

- Integration with, e.g., Schneid API, csv-based databases and Influx databases

- Processing and visualisation also from manual measurements

- Interfaces to Belimo energy valves with local storage and optional cloud connection

Scheiber Solutions will implement a GIS representation of the district heating platform in dashboards for all stakeholders. eKUT and the Industrial Science Institute will focus on analyzing new business models related to demand response, end-user engagement, and smart home connectivity. Finally, the Upper Styria Energy Agency will examine the legal aspects of these new business models and formulate the necessary policy changes regarding data usage, dynamic tariffs, etc.

The following model solutions were being developed in the DOPPLER project:

Digital twin for optimizing district heating networks

Gamification as an incentive for customer involvement in demand response measures

Business models for demand response measures in district heating networks

Media reports on the project

Optimised dimensioning and operational planning of district heating systems – TGA 2024 (special edition, german only)

The DOPPLER project is developing a system-wide platform for district heating planning and operation that integrates all components such as generation, distribution and consumption. The project is being carried out as part of the Green Energy Lab research initiative. (page 8)

To the article